Modelling Titanium Deformation

I completed this thesis as part of my MSc in Materials Science and Engineering at Imperial College London. The goal of the project was to improve the accuracy of crystal plasticity titanium deformation models by approximating three-dimensional grain structure based on two-dimensional imaging techniques.

The understanding macroscopic mechanical properties of a material, such as fatigue life and yield stress, is crucial for the material’s use in engineering applications. These mechanical properties are determined by interactions at the microstructural level. Crystal plasticity models allow for the simulation of material deformation while measuring quantities, such as residual stresses, that are difficult or impossible to measure experimentally but play a key role in determining mechanical properties.

Crystal plasticity models, such as the crystal plasticity fast Fourier transform (CPFFT) model used in this project, require a three-dimensional volume element that represents the material of interest. The goal of this project was to create a method for generating a representative volume element (RVE) from a reference surface. To accomplish this goal, I used stereological analysis combined with a modification of the Voronoi tessellation to allow for morphological anisotropy.

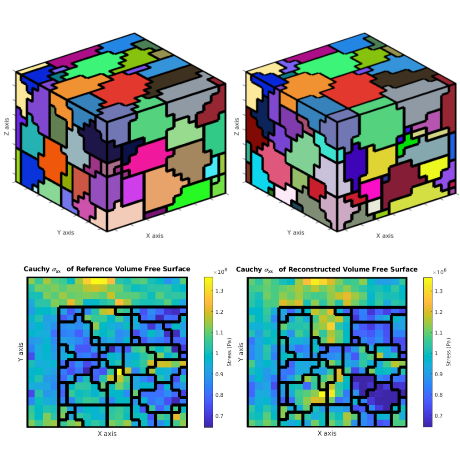

My final model, the Anisotropic Voronoi Model, succeeded in accurately determining grain size and aspect ratio distributions from a reference surface. The outputs of the model were also validated by reconstructing a reference volume from its surface and comparing the output stresses when each volume was deformed in CPFFT simulations. This analysis revealed a dependence of stress concentration on grain aspect ratio, which can be explained by the increased grain boundary area for high aspect ratio grains.